Projektingenieure Dr. Jung und Partner

For over 20 years, our company "PI" has been a cross-industry partner to medium-sized companies and corporates with technologically sophisticated value chains.

The aim of our projects is to increase the productivity and agility of these value chains, often in the course of new products, new processes, new capacities, or new sites.

PI's expertise ranges from the design of the production structure (“Structure”) to factory planning (“Technology”) and the implementation of lean production (“Processes”).

Our clients include Audi, BMW, GE, MAN, Mercedes-Benz, Siemens, VW and ZF.

Services

We design your production

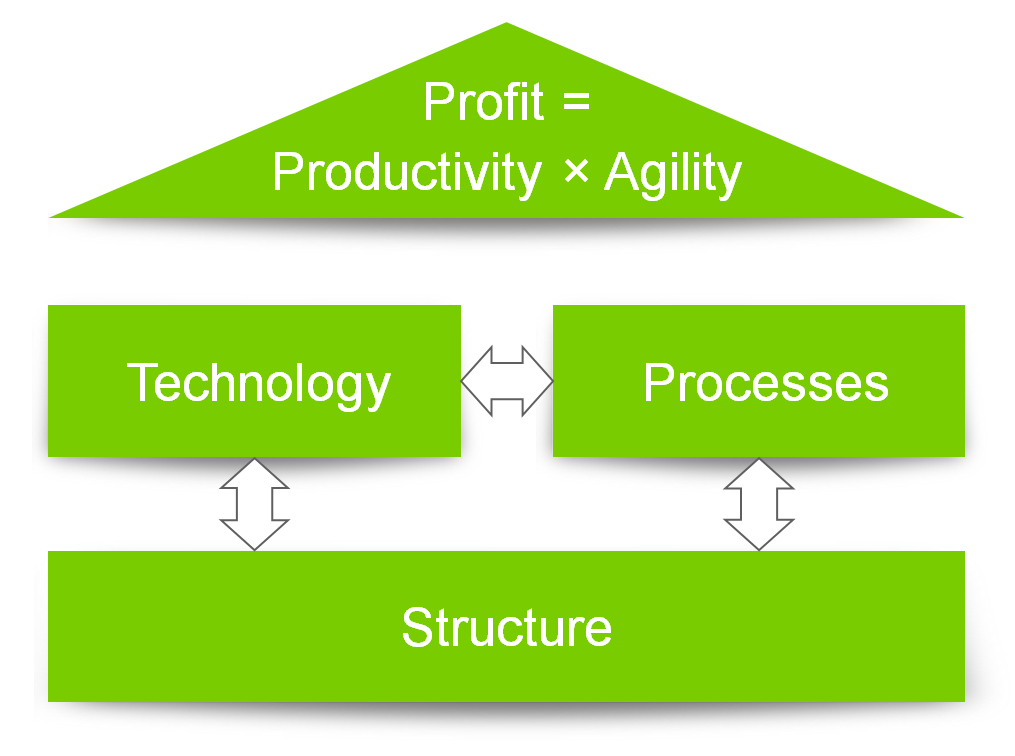

MOTIVATION: PRODUCTIVITY x AGILITY = PROFIT

Production is continuously changing, driven by evolving markets, introducing new technologies, new processes and new structures. The focus remains unchanged: High productivity and high agility constitute the foundation for lasting profits.

High productivity requires robust processes within lean and tailored structures. Small batches and mass production undergo identical processes, and may see the same equipment. The production works in sync with customer takt time, at minimum inventories and swift quality feedbacks. The correct level of automation balances between speed, quality and reproducibility on one hand and lean manufacturing on the other. The staff is striving for perfection.

Agility allows adjusting to fluctuating volumes, new products, and innovative technologies in a simple and flexible approach. Processes are changeable and scalable, personnel is qualified and highly motivated. Agility decreases the cost for change and enables a price premium from short time to market.

How can you increase the productivity and agility of your production?

By designing the production structure, technologies, and processes.

We support you on this endeavor, with good ideas, profound expertise, and professional implementation.

OUR SERVICES:

Structure – We align your resources

How to design your product for production? How to produce variants cost-effectively? What to manufacture yourself and what to buy in? Where to manufacture? How to integrate your suppliers? Which manufacturing principle to implement: workshop, island, line, or matrix manufacturing?

We advise you on defining your production and logistics goals and aligning your resources. We support your projects from potential analysis to implementation, e.g., of a new cross-location manufacturing structure.

The topics of our projects are:

- Product design: design-to-cost, standardization, variant management

- Process design: process cost calculation, vertical integration, make-or-buy, production sites, footprint, supplier network, production segments, production principle

Technology – We plan your factory

FACTORY PLANNING, PROCESS PLANNING, LOGISTICS PLANNING

How can you get production flowing, even with large products? Which manufacturing equipment to choose? How much automation and interlinking is economical? How to transport and store goods? Which layout creates short distances and enables flexibility? How can you grow step by step, both in your existing premises and with a new building?

In a creative dialogue, we develop a cost-effective overall concept with innovative detailed solutions for your task. We plan turnkey plants, from a blank sheet of paper to the approved factory. Also as general planners.

The topics of our projects are:

- Factory planning: value stream, production segments, simulation of capacity requirements and movements, material flow, layout, facilities/infrastructure/buildings, cleanliness, environmental protection, greenfield vs. brownfield

- Process planning: Process engineering, plant engineering, automation, interlinking, energy efficiency, IT, control technology, machine and process data acquisition, Industry 4.0

- Logistics planning: Material supply strategy-by-part, simulation of movements/inventories, load carrier design, conveyor technology: warehouse technology/transport technology, order picking technology, IT, material flow, layout, buildings, fire protection

Our approach complies with VDI 5200 for factory planning.

Processes – We improve your manufacturing and logistics processes

How to implement lean production? What does it mean to manufacture in sync with customer demand? How to implement Kanban, supermarket, and JIS? How to implement “perfection” in manufacturing? How to adapt or introduce new systems?

We identify the causes of waste and performance barriers and design a program for the sustainable improvement of your manufacturing processes and QA procedures. Based on transparency and motivation, we pragmatically introduce the new processes with your team.

The topics of our projects are:

- Manufacturing consulting: SMED, OEE, fault analysis, visualization, CIP, FMEA, standards

- Logistics consulting: Flow principle, cycle time, pull principle, Kanban, JIT, JIS, supply chain management

We got to know PI as proficient, reliable and very easy to work with.

Ferdinand Stutz, GEORG FISCHER AG, Member of the board and CEO GF Automotive

References

Our projects (selection)

Our industries

Our customers come from the following industries

Customer quotes

PI was a proficient and dependable partner along the entire path from first concept to start of serial production. Jointly, we implemented a fascinating and challenging project, and built a cutting-edge foundry ranking among the world‘s finest.

PI has become a strategic partner for GE in key planning and design phases for our new production facilities. PI's impressive expertise in factory planning and consistently first-class solutions distinguish PI from other engineering companies.

PI has planned our new foundry in North Carolina, USA. PI is a complete solution from the earlier stages, starting with ideas and a conception, to the planning, to the installation and rum up. - The best technical and professional engineer consultant team have ever worked with.

PI has supported us in several challenging projects, from the planning of our 10-year plant development to the implementation of complex manufacturing cells. - We value PI as an extremely competent partner with excellent ideas and a professional and pleasant working style.

Our production is a mixture of single part and serial production. It continuously must react faster and more flexible on our customer demands. To achieve this PI supported us with sound concepts and innovative detail solutions.

PI was a factor of success in our factory planning: Proficient, high-performing, team-oriented, entrepreneurially thinking and acting to serve our corporation. Additionally, PI was a trustworthy sparring partner.

Our Team

Dr. Christian Jung

PartnerCV

>PhD (doctorate)

>Dipl.-Ing. (univ)

Markus Pfeiffer

PartnerCV

>Dipl.-Ing. (univ)

Daniel Minnich

PartnerCV

>Dipl.-Ing. (univ)

Our team consists of highly-qualified engineers with management know-how and industrial expertise.

We get to the bottom of your issues. You receive a well-founded solution and a targeted implementation.

Contact

Contact us

Projektingenieure mbH

Dr. E. Jung und Partner

Stifterweg 3, D-82057 Icking

Dr.-Ing. Christian Jung

T +49 8178 9250-45

1234 (at) projektingenieure.de